Technicial Specifications

| Engine Output - SAE J1995 | 615 kW |

| Bucket Payload | 14.6 t |

| Operating Weight | 140 t |

| Note | Specifications shown above apply to highly regulated, backhoe configuration. Lesser regulated and frontless configurations are also available. |

| Engine Model | Cat® C27 |

| Gross Power - SAE J1995 | 615 kW |

| Net Power - SAE J1349 | 556 kW |

| Number of Cylinders | 12 |

| Bore | 137.2 mm |

| Stroke | 152.4 mm |

| Displacement | 27 l |

| Engine Model | Cat® C27 |

| Gross Power - SAE J1995 | 626 kW |

| Net Power - SAE J1349 | 556 kW |

| Number of Cylinders | 12 |

| Bore | 137.2 mm |

| Stroke | 152.4 mm |

| Displacement | 27 l |

| Aspiration | Turbocharged and air-to-air aftercooled |

| Operating Weight | 140 t |

| Ground Pressure | 16.3 N/cm² |

| Note | Operating weight includes: 700 mm (28 in) track shoes, 7.6 m (24 ft 11 in) boom, 3.4 m (11 ft 2 in) stick, standard rock bucket, 100% fuel and lubricants |

| Operating Weight | 140000 kg |

| Standard | 700 mm |

| Wide | 900 mm |

| Extra Wide | 1000 mm |

| Number of Shoes - Each Side | 46 |

| Number of Track Rollers - Each Side | 9 |

| Number of Carrier Rollers - Each Side | 3 |

| Track Pads | Double grouser |

| Travel Speed - Two Stages - 1st Stage - Maximum | 2.3 km/h |

| Travel Speed - Two Stages - 2nd Stage - Maximum | 3.3 km/h |

| Maximum Drawbar Pull - Forward | 858 kN |

| Maximum Drawbar Pull - Reverse | 983 kN |

| Gradeability - Travel Drives | Approximately 42% |

| Hydraulic Track Tensioning | With accumulator |

| Maximum Drawbar Pull | 800 kN |

| Fuel Tank | 1700 l |

| Cooling System | 165 l |

| Engine Oil | 87 l |

| Swing Drive | 9 l |

| Hydraulic System - Including Tank | 1752 l |

| Hydraulic Tank | 956 l |

| Grease Tank | 68 l |

| System Voltage | 24 V |

| Batteries | 4 × 200 Ah (12 V each) |

| Alternator Rating | 150 A (24 V) in total |

| Components (1) | Emergency stop in cabin, engine module, pump room and on service station accessible from ground level |

| Components (2) | Four maintenance free batteries |

| Components (3) | Lockable battery isolation switch |

| Components (5) | 14 LED high-brightness working lights |

| Components (4) | 5 LED service lights |

| Components (6) | 2 electric horns |

| Components (7) | Two (2) lights for rear end |

| Components (9) | One (1) beacon light on cabin roof |

| Components (8) | One (1) light for machine deck/service |

| Main Pumps | 3 × variable swash plate pumps |

| Main Pumps - Maximum Total Oil Flow | 1544 L/min |

| Main Pumps - Maximum Pressure - Attachment | 320 bar |

| Pilot Pump | 1 × gear pump |

| Pilot Pump - Maximum Flow, Pilot | 153 L/min |

| Pilot Pump - Maximum Pressure, Pilot | 95 bar |

| Main Pumps - Maximum Pressure - Travel | 320 bar |

| Swing Pump | 1 × variable swash plate pump |

| Engine Fan Pump - Maximum Flow, Engine Fan | 201 L/min |

| Engine Fan Pump - Maximum Pressure, Engine Fan | 220 bar |

| Engine Fan Pump | 1 × variable swash plate pump |

| Hydraulic Fan Pump - Maximum Flow, Hydraulic Fan | 86 L/min |

| Swing Pump - Maximum Flow - Swing | 479 L/min |

| Hydraulic Fan Pump | 1 × variable swash plate pump |

| Hydraulic Fan Pump - Maximum Pressure, Hydraulic Fan | 135 bar |

| Swing Pump - Maximum Pressure - Swing | 365 bar |

| Hydraulic Oil Cooling - Maximum Flow | 1075 L/min |

| Hydraulic Oil Cooling - Diameter of Fan | 1016 mm |

| Filters (1) | Full-flow high-pressure filters (200 μm) for main pumps |

| Filters (2) | Full-flow filters (20 μm) for complete return circuit |

| Filters (3) | Pressure filters (16 μm) for servo circuit |

| Filters (4) | Full-flow filters (6 μm) for engine cooling return circuit |

| Filters (5) | Swing charge filter (15 μm) |

| Filters (6) | Pump case return screens (125 μm) |

| Swing Drive | Two (2) compact planetary transmissions with axial piston motors |

| Parking Brake | Wet multiple disc brake, spring-loaded/hydraulically released |

| Maximum Swing Speed | 4.9 r/min |

| Swing Ring | Cross roller bearing with sealed internal gearing |

| Features (1) | Closed-loop swing circuit with speed control |

| Features (2) | Hydraulic braking of swing motion when control is returned to neutral position or by counteracting control for stronger braking |

| Features (3) | All raceways and the internal gearing of swing ring supplied by automatic central lubrication system |

| Emissions | U.S. EPA Tier 4 Final and EU Stage V; China Nonroad Stage III, equivalent to U.S. EPA Tier 2; Equivalent to U.S. EPA Tier 1 |

| Feature | Accessible from ground level |

| Equipped With (1) | Emergency stop |

| Equipped With (2) | Quick couplings for: Diesel fuel and Grease |

| Travel Speed - Two Stages - 1st Stage - Maximum | 2.6 km/h |

| Travel Speed - Two Stages - 2nd Stage - Maximum | 3.7 km/h |

| Maximum Drawbar Pull - Forward | 858 kN |

| Maximum Tractive Force | 877 kN |

| Maximum Drawbar Pull - Reverse | 983 kN |

| Gradeability - Travel Drives | 38°/78% (SAE J1309) |

| Hydraulic Track Tensioning | With accumulator |

| Number of Shoes - Each Side | 46 |

| Number of Track Rollers - Each Side | 9 |

| Number of Carrier Rollers - Each Side | 3 |

| Components (1) | Forged double-grouser track pads |

| Components (2) | Chain links connected by hardened pins and bushings |

| Components (3) | Postive Pin Retention (PPR2) sealed and greased track design |

| Components (4) | All running surfaces of sprockets, idlers, rollers and track chain links hardened |

| Components (5) | Fully hydraulic self-adjusting track tensioning system with accumulator |

| Components (6) | Automatic hydraulic retarder valve to prevent overspeed on downhill travel |

| Components (7) | Audible travel alarm |

| Components (1) | Pressurized operator station with positive filtration |

| Components (2) | Heated cab mirror |

| Components (3) | Sliding upper door window (left-hand cab door) |

| Components (4) | Glass-breaking safety hammer |

| Components (5) | Removable lower windshield with in cab storage bracket |

| Components (6) | Joystick Controls Alternate Patterns including ISO/JIS, BHL, MHI, KOBE, or SCM |

| Components (7) | Beverage holder |

| Components (8) | Literature holder |

| Components (9) | AM/FM radio |

| Components (10) | Radio with MP3 auxiliary audio port |

| Components (11) | Two stereo speakers |

| Components (12) | Storage shelf suitable for lunch or toolbox |

| Components (13) | Color LCD display with warning, filter/fluid change, and working hour information |

| Components (14) | Adjustable armrest |

| Components (15) | Height-adjustable joystick consoles |

| Components (16) | Neutral lever (lock out) for all controls |

| Components (17) | Travel control pedals with removable hand levers |

| Components (18) | Two power outlets, 10 amp (total) |

| Components (19) | Laminated glass front upper window and tempered other windows |

| Capacity - Grease Barrel | 68 l |

| Type (1) | Central bank lubrication system |

| Type (2) | Grease is automatically applied to all attachment pivot points (except bucket linkage) and slew bearing |

| Type (3) | Standard grease reel on machine for bucket linkage |

| Type (4) | Grease refill service point accessible from ground |

| Type (1) | Boom and stick torsion-resistant with welded box design |

| Type (2) | High-tensile steel with solid steel castings at pivot areas |

| Type (3) | Boom and stick stress-relieved after welding |

| Type (4) | Float valve for boom down function |

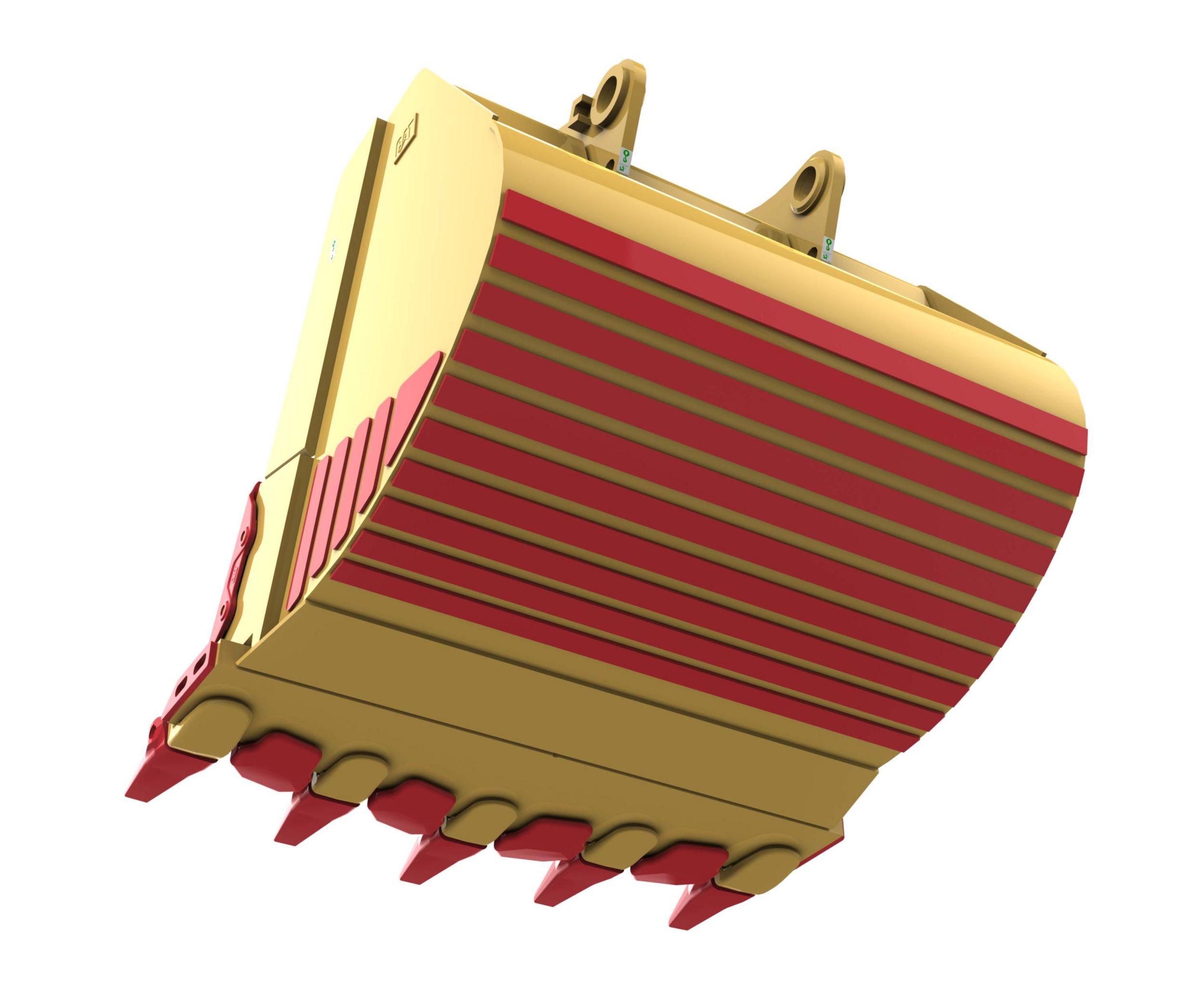

| Buckets Equipped With | – Special liner material covering main wear areas inside and outside – Lip shrouds – Wing shrouds – Heel shrouds |

| Maximum Digging Depth | 8 m |

| Maximum Digging Reach | 13.9 m |

| Maximum Digging Height | 12.8 m |

| Maximum Dump Height | 8.5 m |

| Bucket Digging Force - ISO | 538 kN |

| Bucket Digging Force - SAE | 501 kN |

| Stick Digging Force - ISO | 466 kN |

| Stick Digging Force - SAE | 439 kN |

| Capacity 1:1 | 8.1 m³ |

| Total Width | 2682 mm |

| Number of Teeth | 5 |

| Tooth System | Cat C70 or M75 |

| Weight - Including Standard Wear Package | 8401 kg |

| Maximum Material Density - Loose | 1.8 t/m³ |

Advantages and Features

SAFETY

- Operator Protective Guard (Top Guard) certified cab plus optional front guard.

- Excellent visibility with unobstructed view of digging environment and upward view through skylight, plus optional two-camera system to reduce blind spots and enhance situational awareness.

- Safer access and egress with anti-slip walkways and optional powered 45-degree access stairway.

- Five emergency shut-off switches, with one easily accessible in the cab to shut down the electrical system in case of emergency.

- Safer service with lockable starter and battery isolation switch cabinet.

OPERATOR CAB

- Heated, pneumatically-cushioned and fully adjustable suspension seat that provides height and weight adjustments, lumbar support, wide arm/wrist rests and a wide retractable seat belt for full operator comfort and support.

- Maintained internal ambient temperature with air conditioning, heat and defroster, and improved filtration with fresh air filter that removes dust and particles, plus a second internal filter that cleans recirculated air inside the cab.

- Easily accessible ergonomic joysticks with Electronic-Hydraulic Servo Control, which delivers dynamic and precise response and ensures no hydraulic lines are present in the cab.

- Large, 7 in (178 mm) color touchscreen for convenient troubleshooting and service assistance.

- Independently adjustable joystick consoles, plus joystick controls that allow pattern to be changed for enhanced safety and improved operator experience.

RELIABILITY & DURABILITY

- Rugged Cat heavy duty undercarriage designed to increase uptime, deliver longer service life and withstand increased tramming over rough mine site terrain, with features such as grease lubrication, GLT4 sealing technology and oil-filled rolling components that help it last at least 2,000 hours longer than dry track designs.

- Cat exclusive Positive Pin Retention 2 (PPR2) track design, which mechanically locks the link to the pin to resist pin walking and link cracking to deliver reliable sealing and maximum track life.

- Heavy duty fixed-axle rollers and idlers for improved performance, increased wear life, reduced internal friction and overheating, and elimination of grease consumption and lines.

- Heavy duty track group, which handles high field loads, and reduced pitch extension wear, which increases track chain life by 20% to 40%.

- Structures designed and fabricated to withstand the toughest digging conditions, with high-strength steel; full penetration, profiled and ground welds at critical junctures; and booms and sticks that are stress-relieved after welding.

- Efficient Independent Oil Cooling system, which protects and extends the life of hydraulic components.

- Improved hydraulic system for reduced crosstalk, less cross-contamination and new electrical integration for updated lighting and sensors.

- New suction header and swing pump for better inlet routing.

- Segregated case drain lines with new return hoses and tubes.

- Improved engine enclosure, main control valve mounting bracket and main frame.

PRODUCTIVITY & PERFORMANCE

- Faster cycle times and increased productivity thanks to Cat C27 engine, which is the most powerful in its class and provides top performance over an exceptional service life.

- Fast cycle times and improved energy efficiency delivered by closed-loop swing system, which also generates less heat.

- Proportional Priority Pressure Compensating (PPPC) hydraulic system, which varies hydraulic oil flow for smooth, predictable operation and greater operator efficiency.

- Load Enhanced Anticipatory Control (LEAC), which ensures faster and more consistent engine regulation by preventing lug, which, in turn, reduces fuel consumption.

- Engine Torque Load Control (ETLC), which reduces hydraulic pump output based on available engine torque, desired engine speed, actual engine speed and estimated hydraulic load — providing power to the functions that need it to move material quickly and efficiently.

BUCKETS & GET

- Buckets and ground engaging tools (GET) designed to maximize durability and productivity, ideally matched to your shovel and application, and rebuildable, with wear components available as service parts.

- Integrated to work as part of a machine system — helping you achieve high productivity and the lowest cost per ton.

- Hammerless GET designed specifically for the 6015, with no special tools required for removal and installation.

- New standard rock bucket equipped with the new M75 GET, which is 20% stronger than the previous C70 GET and moves 8.1 m3 (10.6 yd3) of material, carrying up to 14.6 tonnes (16.1 tons).

- Wear packages that protect your investment, including special liner material and lip shrouds, wing shrouds and heel shrouds.

CONNECTIVITY & TECHNOLOGY

- Greater connectivity with improved Product Link™ Elite system, which increases the availability of data provided by the 6015 and allows it to collect and transmit information into locally hosted or cloud-hosted applications.

- Factory-ready for Cat MineStar™ Solutions, with a range of capabilities that meet the needs of your fleet.

- MineStar Health, which lets you collect and monitor machine data so you can be proactive and maximize uptime.

- MineStar Edge™, which makes it possible to measure, manage, analyze and optimize your entire operation.

- Designed for the future, with expandable electronic systems that allow smooth integration of MineStar or other electronic capabilities.

SERVICEABILITY

- Access to Cat Electronic Technician, which helps dealer service personnel more easily diagnose and prevent issues.

- Enhanced warning levels for hydraulic oil temperature and improved data link diagnostics for reduced downtime.

- Visual inspection ports for slew drive pinions and ring gear, commonization of charging ports and charging tool and new electronic pilot pressure monitoring via ET.

- Ground-level service station that provides easy access to fast-fill diesel fuel and grease connections.

- Maintenance-free Positive Pin Retention tracks that are specially machined to extend internal pin/bushing wear life and fatigue resistance.

- Larger, heavier hydraulic tank for improved performance.

- New hydraulic oil cooler configuration is easier to service.

- Second cooling core for increased capacity.

- Externally routed margin relief drain ports.

SUSTAINABILITY

- Highly regulated C27 engine certified to meet U.S. EPA Tier 4 Final/EU Stage V emissions standards without the need for DEF — saving time and cost during maintenance.

- Reduce fuel consumption with Load Enhanced Anticipatory Control (LEAC) system.

- Sound-suppressed power module to keep spectator sound levels low.

- Preservation of raw materials, energy conservation and reduced emissions through the Cat Reman and Cat Rebuild programs, which return end-of-life components to like-new condition.

Standard Equipment

-

Cat Powertrain

- 2 x Cat 3512E engines

- Aftertreatment System (used in highly regulated countries only): – Diesel Oxidation Catalysts (DOCs) – Non-DEF solution

- Air-to-Air After Cooling (ATAAC)

- Turbocharger

- Hydraulically driven radiator fan

- Electronically controlled fan speed

- Micro processed engine management

- Heavy-duty air filters

- Two-stage fuel filter with series filtration

- High-capacity water seperator

- Starting aid -- automatic ether

- Exhaust manifold and turbo heat shields

- Dual 24 V electric starters per engine

- Automatic engine idle shut down

- Automatic fuel priming

-

Hydraulics

- Hydraulic Optimization

- Operator Assist: Enhanced Motion Control

- Cat Hydraulic Hose assemblies

- Pump managing system with: – Electronic load limit control – Flow on demand – Automatic zero flow regulation – Automatic engine rpm reduction – Reduced oil flow at high hydraulic oil or engine temperature

- Pressure cut-off for main pumps

- Cooling of pump transmission gear oil

- Closed loop swing circuit

- Pressure testing points

- Full-flow high-pressure filters (100 μm), main pumps

- High pressure filters (100 μm), closed swing circuit

- Full-flow filters (10 μm), return circuit

- Pressure filters swing charge circuit (40 μm)

- Pressure filters pilot circuit (6 μm)

- Transmission oil filters (40 μm)

- Boom float valve (FS and BH)

- Stick float valve (FS)

-

Electrical System

- 6 Maintenance-free batteries

- Lockable battery isolator switch

- Lockable starter isolator switch

- 13 LED high-brightness working flood lights

- 17 LED service lights

- 2 acoustic travel alarms – forward and reverse (power module, oil cooler module)

- 2 electric horns (1 cab module, 1 oil cooler module)

-

Undercarriage

- HD tracks with cast double-grouser track pads

- 1400 mm (4'7") wide track pads

- HD fixed axle carrier and load rollers

- HD fixed axle idlers

- Automatic hydraulic retarder valve

- Hinged travel motor covers

- Hardened running surfaces of sprockets, idlers, rollers, pad links, teeth contact areas

- Fully hydraulic self-adjusting track tensioning system with piston accumulators

-

Automatic Lubrication System

- Rectangular grease container (fill via service station)

- Lubricated pinion in swing ring

- Grease filters (200 μm)

-

Operator Environment

- Single hydraulically driven HVAC system

- In-floor window with removable grate

- Pneumatically cushioned and multiadjustable comfort seat with: – Heating and cooling – Lumbar support – 2-point safety belt – Head and arm rests – Safety switch for automatic motion shutdown

- Independently adjustable seat consoles with integrated joysticks

- Electronic-Hydraulic Servo Control

- Elevated full-size trainer seat with 2-point safety belt and laptop desk

- Additional fold-away auxiliary seat with 2-point safety belt

- Three cup holders

- FM/AM radio with USB and AUX input

- Parallel intermittent wiper/washer

- Roller blinds

- Monitoring system with 254 mm (10 in) color touchscreen

- 45° stairway from engine bay to operator cab

- Powered 45° access stairway

- Heated mirror on LH side

- Camera monitoring system (Right and rear cameras, 2 lights, and additional display)

- Level indicators for length and crosswise inclination

- Document Storage

-

Front Attachment

- Service access holes from both sides in boom and stick (FS and BH)

- Boom and stick thermally stress relieved after welding

- Catwalks with rails at boom (FS and BH)

- Wear Package (as per bucket selection)

-

Cat Technology

- Cat Product Link™ Elite (Cellular)

- Cat MineStar™ Solutions Ready

-

Service and Maintenance

- Engine oil exchange interval -- 500 hours

- Hydraulic oil change interval – 10,000 hours

- Scheduled Oil Sampling (S·O·SSM) ports

- Retractable ground level service station with quick couplings for: – Diesel fuel – Engine coolant – left/right engines – Pump transmission gear oil – left/right engines – Engine oil – left/right engines – Engine oil extension tanks – Hydraulic oil – Grease – Swing transmission gear oil

- Cat battery charging connector

- Indicator lights

- Cat Electronic Technician service port

- Dirt wiper at swivel

-

Safety and Security

- Emergency stop switches: 2 in cab, 5 in engine module, 1 at ground level service station, 1 pull rope accessible from ground level

- Operator Protective Guard (Top Guard)

- All-round safety glass

- Emergency egress ladder

-

Miscellaneous

- ISO or ANSI decals

Optional Equipment

-

UNDERCARRIAGE

- Track guards – full length

- Track guards – center

- Track width: – Standard – 700 mm (28 in) – Wide – 900 mm (36 in) – Extra Wide – 1000 mm (39 in)

-

COLD WEATHER OPTIONS

- Starting aid – cold weather

- 120 V or 240 V cold weather package

- Fuel heater

- Heated cab mirror

- Lubricant options include: low temperature, high temperature, and Cat Bio HYDO Advanced

-

SUPERSTRUCTURE

- Copper Mesabi or aluminum bar plate engine cooling packages

- LED working lights

- Powered 45° access stairway

- Camera Monitoring System (2 cameras and additional color display)

-

CAB

- Operator Protective Guard (Front Guard)

- Product Link Elite radio options (Cellular, Satellite, No Radio)

-

ATTACHMENT

- 3.4 m (11 ft 2 in) or 4.1 (13 ft 5 in) stick

-

BUCKETS

- Additional buckets available, based on application, through your local Cat dealer