Technicial Specifications

| Engine Power - ISO 14396:2002 | 335 kW |

| Engine Model | Cat® C15 |

| Peak Power Speed | 1600 |

| Gross Power - SAE J1995:2014 | 340 kW |

| Net Power - SAE J1349:2011 | 278 kW |

| Rated Speed | 2000 |

| Rated Speed - 2,000 rpm - EEC 80/1269 | 278 kW |

| Rated Speed - 2,000 rpm - ISO 9249 | 278 kW |

| Bore | 137 mm |

| Stroke | 171.5 mm |

| Displacement | 15.2 l |

| Peak Torque (1,200 rpm) - SAE J1995:2014 | 2411 N·m |

| Torque Rise | 16% |

| Note (1) | Two engine emission options are available: 1. Meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 emission standards. 2. Meets Brazil MAR-1 emission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA. |

| Note (2) | Net power advertised is the power available at the flywheel when the engine is equipped with fan at minimum speed, air intake system, exhaust system, and alternator. |

| Operating Weight - Standard | 44355 kg |

| Bucket Capacity Range | 5.0-10.3 m³ (6.5-13.5 yd³) |

| Operating Weight - High Lift | 47175 kg |

| Rated Payload - Standard (Quarry Face) | 10 t |

| Rated Payload - Loose Material (Standard) | 12.7 t |

| Rated Payload - High Lift (Quarry Face) | 10 t |

| Rated Payload - Loose Material (High Lift) | 11 t |

| Cat Truck Match - Standard | 770/735/740/745 |

| Cat Truck Match - High Lift | 772/773 |

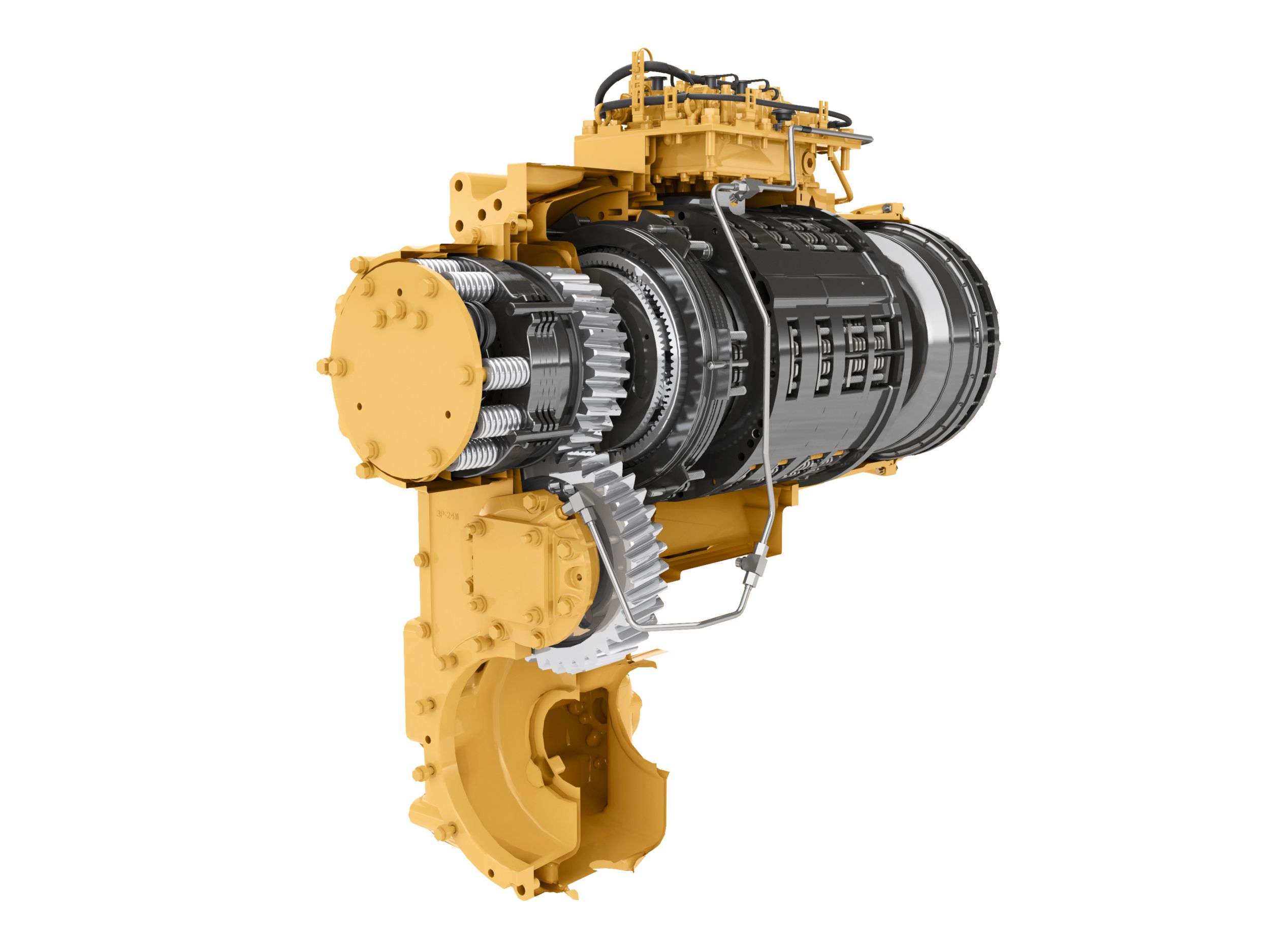

| Transmission Type | Cat planetary power shift |

| Forward - 1 | 7.3 km/h |

| Forward - 2 | 12.2 km/h |

| Direct Drive - Forward 2 | 12.7 km/h |

| Direct Drive - Forward 3 | 22 km/h |

| Direct Drive - Forward 4 | 39 km/h |

| Reverse - 1 | 7.6 km/h |

| Reverse - 2 | 13.6 km/h |

| Direct Drive - Reverse 2 | 14.1 km/h |

| Direct Drive - Reverse 3 | 25 km/h |

| Direct Drive - Reverse 4 | 40.8 km/h |

| Lift/Tilt System - Circuit | Load Sense |

| Lift/Tilt System - Pump | 2 × 110 cc variable displacement |

| Maximum Flow at 2,165 rpm | 470 L/min |

| Relief Valve Setting - Lift/Tilt | 27900 kPa |

| Lift Cylinder - Bore | 190 mm |

| Lift Cylinder - Stroke | 1138 mm |

| Tilt Cylinder - Bore | 170 mm |

| Tilt Cylinder - Stroke | 722 mm |

| Rack Back | 4.5 s |

| Raise | 9 s |

| Dump | 3.5 s |

| Lower | 5.2 s |

| Lower Float Down | 4.3 s |

| Total Hydraulic Cycle Time | 21.3 s |

| Steering System - Circuit | Load Sense |

| Steering System - Pump | Piston, variable displacement |

| Maximum Flow at 1,400 rpm | 200 L/min |

| Steering Cut Off Pressure | 27600 kPa |

| Total Steering Angle | 70° |

| Air Conditioning | The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a or R1234yf. See the label or instruction manual for identification of the gas. - If equipped with R134a (Global Warming Potential = 1430), the system contains 1.8 kg (3.9 lb) of refrigerant, which has a CO2 equivalent of 2.574 metric tonnes (2.837 tons). |

| Front | Fixed |

| Rear | Trunnion |

| Oscillation Angle | ±12.5° |

| Oscillation Angle - Chain Arrangement | ±8.5° |

| Brakes | ISO 3450:2011 |

| ROPS/FOPS | ROPS/FOPS meet ISO 3471:2008 (ROPS) and ISO 3449:2005 Level II (FOPS) |

| Fuel Tank | 535 l |

| Fuel Tank - Short Lift | 481 l |

| Cooling Systems | 100 l |

| Crankcase | 34 l |

| Diesel Exhaust Fluid Tank | 23 l |

| Transmission | 75 l |

| Axle Oil - Differentials and Final Drives - Front | 186 l |

| Axle Oil - Differentials and Final Drives - Rear | 170 l |

| Hydraulic System Factory Fill | 330 l |

| Hydraulic System - Tank Only | 130 l |

| Operator Sound Pressure Level (ISO 6396:2008) | 73 dB(A) |

| Machine Sound Power Level (ISO 6395:2008) | 113 dB(A) |

| Operator Sound Pressure Level (ISO 6396:2008)* | 72 dB(A) |

| Machine Sound Power Level (ISO 6395:2008)** | 110 dB(A) |

| Note (1) | * For machines in European Union countries and in countries that adopt the “EU Directives” and “UK Directives.” |

| Note (2) | ** European Union Directive “2000/14/EC” as amended by “2005/88/EC” and UK Noise Regulation 2001 No. 1701. |

| Note (3) | The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed. |

| Note (4) | The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed. |

| Note (5) | Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment. |

| Operator Sound Pressure Level (ISO 6396:2008) | 74 dB(A) |

| Machine Sound Power Level (ISO 6395:2008) | 113 dB(A) |

| Operator Sound Pressure Level (ISO 6396:2008)* | 73 dB(A) |

| Machine Sound Power Level (ISO 6395:2008)** | 110 dB(A) |

| Note (1) | * For machines in European Union countries and in countries that adopt the “EU Directives” and “UK Directives.” |

| Note (2) | ** European Union Directive “2000/14/EC” as amended by “2005/88/EC” and UK Noise Regulation 2001 No. 1701. |

| Note (3) | The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed. |

| Note (4) | The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 70% of the maximum engine cooling fan speed. |

| Note (5) | Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment. |

| Ground to Top of ROPS | 4100 mm |

| Ground to Top of Exhaust Stacks | 4060 mm |

| Ground to Top of Hood | 3270 mm |

| Ground to Center of Front Axle | 978 mm |

| Ground to Fuel Tank Clearance | 691 mm |

| Ground to Lower Hitch Clearance | 459 mm |

| Reach - Maximum Lift | 2175 mm |

| Clearance at Maximum Lift | 3079 mm |

| B-Pin Height - Maximum Lift | 4912 mm |

| Maximum Overall Height - Bucket Raised | 6817 mm |

| Rear Axle - Centerline to Bumper | 3132 mm |

| Wheel Base | 3810 mm |

| Maximum Overall Length | 11143 mm |

| Front Axle Centerline to Bucket Tip | 4201 mm |

| Note | <ul><li>All dimensions are approximate.</li><li>Specifications are calculated with a 6.1 m³ (8.0 yd³) rock bucket.</li></ul> |

| Ground to Top of ROPS | 4100 mm |

| Ground to Top of Exhaust Stacks | 4060 mm |

| Ground to Top of Hood | 3270 mm |

| Ground to Center of Front Axle | 978 mm |

| Ground to Fuel Tank Clearance | 691 mm |

| Ground to Lower Hitch Clearance | 459 mm |

| Reach - Maximum Lift | 2248 mm |

| Clearance at Maximum Lift | 3538 mm |

| B-Pin Height - Maximum Lift | 5371 mm |

| Maximum Overall Height - Bucket Raised | 7276 mm |

| Rear Axle - Centerline to Bumper | 3132 mm |

| Wheel Base | 3810 mm |

| Maximum Overall Length | 11591 mm |

| Front Axle Centerline to Bucket Tip | 4649 mm |

| Note | <ul><li>All dimensions are approximate.</li><li>Specifications are calculated with a 6.1 m³ (8.0 yd³) rock bucket.</li></ul> |

| Ground to Top of ROPS | 4100 mm |

| Ground to Top of Exhaust Stacks | 4060 mm |

| Ground to Top of Hood | 3270 mm |

| Ground to Center of Rear Axle | 978 mm |

| Ground to Fuel Tank Clearance | 691 mm |

| Ground to Lower Hitch Clearance | 459 mm |

| Reach at Maximum Lift | 2437 mm |

| Clearance at Maximum Lift | 3259 mm |

| B-Pin Height at Maximum Lift | 4566 mm |

| Maximum Overall Height, Bucket Raised | 6359 mm |

| Rear Axle Center Line to Bumper | 3132 mm |

| Wheel Base | 3810 mm |

| Maximum Overall Length | 10671 mm |

| Front Axle Centerline to Bucket Tip | 3729 mm |

| Ground to Top of ROPS | 4100 mm |

| Ground to Top of Exhaust Stacks | 4060 mm |

| Ground to Top of Hood | 3270 mm |

| Ground to Center of Rear Axle | 978 mm |

| Ground to Fuel Tank Clearance | 691 mm |

| Ground to Lower Hitch Clearance | 459 mm |

| B-Pin Height at Maximum Lift | 4566 mm |

| Rear Axle Center Line to Bumper | 3132 mm |

| Wheel Base | 3810 mm |

| Maximum Overall Length | 10776 mm |

| Front Axle Centerline to Bucket Tip | 3834 mm |

Advantages and Features

PROVEN RELIABILITY

- The highly responsive Cat C15 engine is built and tested for maximum performance.

- Mechanically actuated Electronic Unit Injection (MEUI™) fuel system and ADEM™ A5 electronic control module manage fuel delivery for optimum performance and quick engine response.

- Available in aggregate handler configuration with 14-ton payload.

- System match efficiency up to 60-ton rigid-frame trucks.

LONG TERM VALUE AND DURABILITY

- World-class transmission for long life and consistent, smooth shifting; specifically designed for mining applications.

- Moves material more efficiently with improved power and control.

- Durable construction withstands the toughest loading conditions and multiple life cycles.

- Transmission neutralizer pedal extends service brake life and allows full power during stationary loading.

- Load sense hydraulics maximize performance, lower heat and fuel consumption.

- Advanced filtration system for extended performance and reliability of the hydraulic system.

PERFORMANCE AND PRODUCTIVITY

- Up to 10% more payload per pass, higher efficiency, and improved pass match.

- Field-proven lift arms for enhanced strength, uptime, and excellent visibility.

- Load-sensing hydraulic steering with 35-degree articulation for precise positioning.

- Maximum responsiveness with Steering and Integrated Control (STIC™), combining directional, gear, and steering controls in a single joystick.

- Most advanced payload weight measuring system available.

- Performance Buckets for superior digging, higher bucket fill factors, and reduced dig times.

- Cat Advansys™ ground engaging tools (GET) protect components and reduce operating costs.

- Excellent visibility to the bucket edges and work area.

- Convenient, responsive, electro-hydraulic controls increase operator productivity.

POWERFUL EFFICIENCY

- World-class efficiency while truck loading.

- Torque converter with lock-up clutch improves travel speed, cycle times.

- Engine Idle Shutdown saves fuel from unnecessary idling. Move up to 10% more material per gallon of fuel.

- Consistent performance and efficiency with lower system heat.

PRODUCTIVITY WITH TECHNOLOGY

- Developed to monitor, manage, and enhance your jobsite operations.

- Payload provides accurate weighing* of the materials you are loading and hauling. Payload data is displayed in real-time to improve productivity and reduce overloading.

- Detect enhances awareness of the environment around working equipment and provides alerts to help keep people and assets safe on the jobsite.

- VisionLink® wirelessly connects you to your equipment, giving you access to essential information you need to know to run your business.

- Gain valuable insight into how your machine or fleet is performing.

- Optional Advanced Productivity subscription provides comprehensive actionable information to help you manage and improve the productivity and profitability of your operations.

*Not legal for trade

SAFETY FIRST

- Standard stairway lighting.

- Left- and right-hand stairs with 45-degree angle.

- Rear vision camera system.

- Large front and side windows.

- Pressurized cabin with filtered and reduced sound levels.

SAVE ON SERVICE AND MAINTENANCE

- Up to 10% lower maintenance costs.

- Advanced filtration system for extended performance.

- Extended service intervals for fluids and filters.

- Ground level or platform access to transmission control valves.

- Grouped service points.

- Centralized, ground level grease points and remote pressure taps.

- Ground electrical service center.

- Reduced waste with maintenance-free or extended-maintenance batteries.

- Swing-out engine compartment service doors.

- Tire pressure monitoring to enhance tire life.

- Longer life, rebuildability, and high resale value.

- Electro-hydraulic controls.

OPERATOR COMFORT AND CONTROL

- World-class operator comfort and ergonomics.

- Integrated steering and transmission controls.

- Convenient, automatic, inside-the-cab implement kickouts.

- Easy-to-use soft detent controls.

- Comfort Series III seats with extra thick, contoured cushions.

- Air suspension system.

- Easy-to-reach levers and controls with six-way adjustment.

- Seat-mounted implement pod with STIC steering.

- Ergonomic switch placement and displays with large backlit switches and LED indicators.

- Two-position rocker switch activates the electro-hydraulic parking brake.

- Automatic cab temperature controls.

- Precise machine control by load-sensing hydraulic steering system.

- Fold-up STIC steer/armrest.

PURPOSE BUILT SPECIALTY MODELS

Block Handler

- Delivers stability and durability with an optimized counterweight for block handling applications.

- An additional hydraulic valve with the Quick Coupler allows the operator to switch work tools and immediately lock the work tool.

- Larger tilt and lift cylinders on the linkage help improve load control and ensure safe and long lasting operation.

- Ride control acts as a shock absorber, providing the operator with a smoother ride over rough terrain.

- Linkage layout designed to maximize lift capability in block handling application.

- High load stresses are absorbed by solid steel lift arms.

- Enhanced strength in key pin areas through the use of one-piece castings.

- Stress released lift arms increase durability and lengthen time to repair.

Standard Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

ELECTRICAL

- Alarm, back-up

- Alternator, single 145 amp

- Batteries, maintenance-free

- Converter, 10/15 amp, 24V to 12V

- Lighting system (LED, work lights, access and service platform lighting)

- Starting and charging system, 24V

- Auxiliary jump start receptacle

-

OPERATOR ENVIRONMENT

- Graphical Information Display, displays real time operating information, performs calibrations and customizes operator settings

- Air conditioner

- Cat Vision, rear vision camera system

- Cat Production Measurement ready

- Cab precleaner

- Cab, sound suppressed and pressurized, integrated rollover protective structure (ROPS/FOPS) radio ready for entertainment, includes antenna, speakers and converter (12-volt 5-amp) and power port

- Controls, lift and tilt function

- Heater, defroster

- Horn, electric

-

Instrumentation, gauges:

– Coolant temperature

– Fuel level

– DEF level

– Hydraulic oil temperature

– Powertrain oil temperature

- Light, cab, dome

- Lunchbox, beverage holders

- Mirrors, rearview (externally mounted)

- Seat, Cat Comfort (cloth), air suspension, six-way adjustable

- Seat belt minder

- Seat belt, retractable, 76 mm (3 in) wide

- Steering and Transmission Integrated Control (STIC™) System

- UV glass

- Transmission gear indicator

-

Wet-Arm wipers/washers (front and rear):

– Intermittent front and rear wipers

- Lights, directional

-

POWERTRAIN

- Brakes, oil-cooled, multi-disc, service/secondary

- Case drain screens

- Crankcase guard

- Electro hydraulic parking brake

- Engine, C15 MEUI diesel, turbocharged/aftercooled

- Ground level engine shutdown switch

- Turbine precleaner, engine air intake

- Starting aid, ether, automatic

- Torque converter, Neutralizer

- Transmission, planetary powershift, 4F/3R electronic control

- Manual switch and automatic fuel priming

-

OTHER

- Automatic bucket lift kickout/positioner

- Hydraulically driven demand fan

- Couplings, Cat O-ring face seals

- Doors, service access (locking)

- Ecology drains for engine, radiator, hydraulic tank

- Fuel tank, 535 L (141 gal)

- Hitch, drawbar with pin

- Hoses, Cat XT™

- Hydraulic, steering and brake filtration/screening system

- Cat® Clean Emission Module

- Oil sampling valves

- Premixed 50% concentration of extended life coolant with freeze protection to –34° C (–29° F)

- Rear access to cab and service platform

- Steering, load sensing

- Toe kicks

- Vandalism protection caplocks

Optional Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

POWERTRAIN

- –50° C (–58° F) antifreeze

- Engine oil change system, high speed, Wiggins

- Engine block heater 120V or 240V

- High ambient cooling – software

-

MISCELLANEOUS ATTACHMENTS

- Front and rear roading fenders

- Fast fill fuel system (Shaw-Aero)

- Cold Weather Starting (extra two batteries)

-

OTHER OPTIONAL CONFIGURATIONS

- Aggregate Handler

- Block Handler

-

OPERATOR ENVIRONMENT

- Cat® Detect, object detection system

- Cat Production Measurement

- AM/FM/CD/MP3 radio

- Satellite Sirius radio with Bluetooth

- LED warning strobe

- CB radio ready

- Window pull down visor

- Handrail mounted mirrors