Technicial Specifications

| Engine Power - ISO 14396:2002 | 586 kW |

| Engine Model | Cat® C27 |

| Emissions | Option 1 - U.S. EPA Tier 4 Final/EU Stage V |

| Rated Speed | 1800 r/min |

| Gross Power - SAE J1995:2014 | 597 kW |

| Net Power - SAE J1349:2011 - Standard Ambient | 546 kW |

| Net Power - SAE J1349:2011 - High Ambient | 508 kW |

| Emissions | Option 2 - Emits equivalent to U.S. EPA Tier 2 |

| Rated Speed | 1800 r/min |

| Engine Power - ISO 14396:2002 | 561 kW |

| Gross Power - SAE J1995:2014 | 571 kW |

| Net Power - SAE J1349:2011 - Standard Ambient | 521 kW |

| Net Power - SAE J1349:2011 - High Ambient | 483 kW |

| Bore | 137.2 mm |

| Stroke | 152.4 mm |

| Displacement | 27.03 l |

| Peak Torque - 1,200 rpm | 3557 N·m |

| Torque Rise | 18 % |

| Note | Net power advertised is the power available at the flywheel when the engine is equipped with fan at minimum speed, air intake sytstem, exhaust system, and alternator. |

| Operating Weight - Standard | 80974 kg |

| Bucket Capacity Range | 8.6 m³ – 10.0 m³ (11.25 yd³ – 13.0 yd³) |

| Rated Payload - Standard | 15.9 t |

| Rated Payload - High Lift | 15.9 t |

| Cat Truck Match - Standard | 773-775 |

| Cat Truck Match - High Lift | 775-777 |

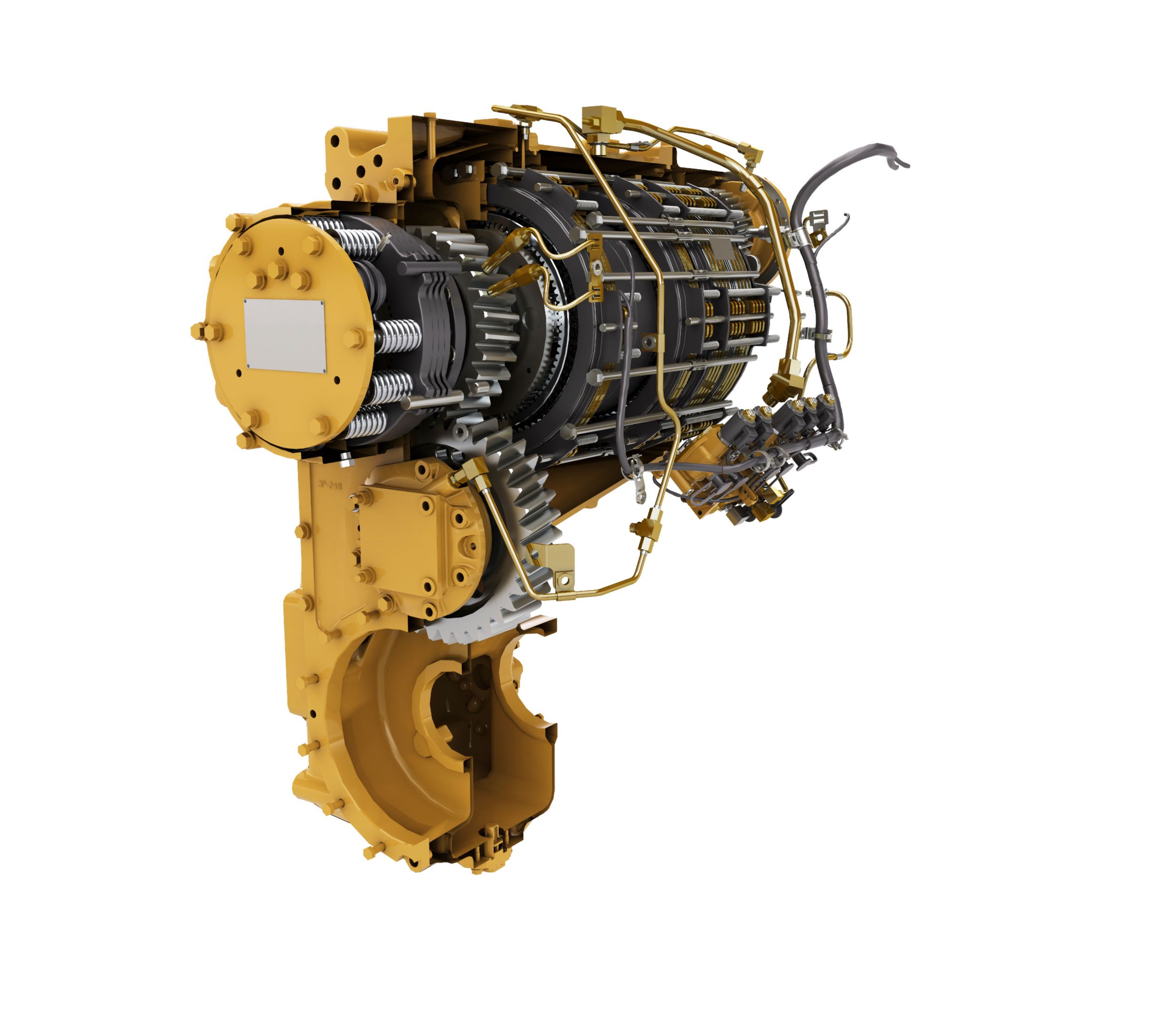

| Transmission Type | Cat planetary power shift |

| Forward - 1 | 7.4 km/h |

| Forward - 2 | 13.2 km/h |

| Forward - 3 | 23.3 km/h |

| Reverse - 1 | 8.15 km/h |

| Reverse - 2 | 14.6 km/h |

| Reverse - 3 | 25.7 km/h |

| Direct Drive - Forward 1 | Lock-up disabled |

| Direct Drive - Forward 2 | 13.2 km/h |

| Direct Drive - Forward 3 | 23.3 km/h |

| Direct Drive - Reverse 1 | 8.15 km/h |

| Direct Drive - Reverse 2 | 14.6 km/h |

| Direct Drive - Reverse 3 | 25.7 km/h |

| Note | Travel speeds based on Michelin 45/65R39 LD D2**L5 tires. |

| Lift/Tilt System - Circuit | Positive flow control |

| Lift/Tilt System | Variable displacement piston |

| Maximum Flow at 1,800 rpm | 910 L/min |

| Relief Valve Setting - Lift/Tilt | 33000 kPa |

| Cylinders, Double Acting - Lift, Bore and Stroke | 235 mm × 1287 mm (9.3 in × 50.7 in) |

| Cylinders, Double Acting - Tilt, Bore and Stroke | 292.1 mm × 820 mm (11.5 in × 32.3 in) |

| Pilot System | Open loop and pressure reducing |

| Pilot Relief Setting | 3500 kPa |

| Rack Back | 4.3 s |

| Raise | 8.6 s |

| Dump | 2.9 s |

| Lower | 3.7 s |

| Lower Float Down | 3.7 s |

| Total Hydraulic Cycle Time - Empty Bucket | 13.8 s |

| Steering System - Circuit | Pilot, load sensing |

| Steering System - Pump | Piston, variable displacement |

| Maximum Flow at 1,400 rpm | 364 L/min |

| Relief Valve Setting - Steering | 34500 kPa |

| Total Steering Angle | 70° |

| Air Conditioning | • The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a or R1234yf. See the label or instruction manual for identification of the gas. • If equipped with R134a (Global Warming Potential = 1430), the system contains 2.7 kg (5.9 lb) of refrigerant which has a CO2 equivalent of 3.861 metric tonnes (4.256 tons). |

| Front | Fixed |

| Rear | Trunnion |

| Oscillation Angle | 8.5° |

| Brakes | ISO 3450: 2011 |

| Fuel Tank | 1064 l |

| Cooling System | 208 l |

| Engine Crankcase | 75.7 l |

| Transmission | 110 l |

| Differential - Final Drives - Front | 271 l |

| Differential - Final Drives - Rear | 261 l |

| Hydraulic System Factory Fill | 795 l |

| Hydraulic Tank - Implement and Hydraulic Fan | 261 l |

| Hydraulic Tank - Steering and Braking | 132 l |

| Note | Cat U.S. EPA Tier 4 Final/EU Stage V diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: • 20% biodiesel FAME (fatty acid methyl ester)* • 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. * Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer). ** Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels. – Cat DEO-ULS™ or oils that meet the Cat ECF-3, API CJ-4, API CK-4, and/or ACEA E9 specifications are required. – Diesel Exhaust Fluid (DEF) that meets all requirements defined in ISO 22241-1:2006. |

| Operator Sound Pressure Level (ISO 6396:2008) | 72 dB(A) |

| Machine Sound Power Level (ISO 6395:2008) | 116 dB(A) |

| Operator Sound Pressure Level (ISO 6396:2008)* | 72 dB(A) |

| Machine Sound Power Level (ISO 6395:2008)* | 114 dB(A) |

| Note (1) | *Sound suppression equipped |

| Note (2) | The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 70 percent of the maximum engine cooling fan speed. |

| Note (3) | The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 70 percent of the maximum engine cooling fan speed. |

| Note (4) | Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment. |

| Operator Sound Pressure Level (ISO 6396:2008) | 72 dB(A) |

| Machine Sound Power Level (ISO 6395:2008) | 116 dB(A) |

| Operator Sound Pressure Level (ISO 6396:2008)* | 72 dB(A) |

| Machine Sound Power Level (ISO 6395:2008)* | 114 dB(A) |

| Note (1) | *Sound suppression equipped |

| Note (2) | The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 70 percent of the maximum engine cooling fan speed. |

| Note (3) | The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 70 percent of the maximum engine cooling fan speed. |

| Note (4) | Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment. |

| Ground to Top of ROPS | 5240 mm |

| Ground to Top of Exhaust Stacks | 5049 mm |

| Ground to Top of Hood | 3862 mm |

| Ground to Bumper Clearance | 1079 mm |

| Rear Axle - Centerline to Bumper | 3795 mm |

| Front Axle Centerline to Bucket Tip | 4689 mm |

| Wheel Base | 4600 mm |

| Maximum Overall Length | 13084 mm |

| Ground to Lower Hitch Clearance | 596 mm |

| Ground to Center of Front Axle | 1290 mm |

| Clearance at Maximum Lift | 4044 mm |

| Rack Back Angle at Ground Level | 40.4° |

| Rack Back Angle at Carry | 48.8° |

| B-Pin Height - Maximum Lift | 6009 mm |

| Maximum Overall Height - Bucket Raised | 8281 mm |

| Rack Angle at Maximum Lift | 63.7° |

| Dump Angle at Maximum Lift | 45° |

| Reach - Maximum Lift | 2194 mm |

| Note | Specifications are calculated with 9.0 m3 (11.8 yd3) rock bucket and Bridgestone 45/65R39 VSDL One Star tires. |

| Ground to Top of ROPS | 5240 mm |

| Ground to Top of Exhaust Stacks | 5049 mm |

| Ground to Top of Hood | 3862 mm |

| Ground to Bumper Clearance | 1079 mm |

| Rear Axle - Centerline to Bumper | 3795 mm |

| Front Axle Centerline to Bucket Tip | 5425 mm |

| Wheel Base | 4600 mm |

| Maximum Overall Length | 13820 mm |

| Ground to Lower Hitch Clearance | 596 mm |

| Ground to Center of Front Axle | 1290 mm |

| Clearance at Maximum Lift | 4521 mm |

| Rack Back Angle at Ground Level | 39.9° |

| Rack Back Angle at Carry | 49.3° |

| B-Pin Height - Maximum Lift | 6470 mm |

| Maximum Overall Height - Bucket Raised | 8742 mm |

| Rack Angle at Maximum Lift | 60.6° |

| Dump Angle at Maximum Lift | 51° |

| Reach - Maximum Lift | 2583 mm |

| Note | Specifications are calculated with 9.0 m3 (11.8 yd3) rock bucket and Bridgestone 45/65R39 VSDL One Star tires. |

Advantages and Features

PROVEN RELIABILITY

- Cat C27 engine is built and tested to meet your most demanding applications.

- Long engine life and improved fuel efficiency with reduced rated speed.

- Designed for long life, rebuildability, and high resale value.

- Maximum responsiveness with Steering and Integrated Control (STIC™).

- Moves more material more efficiently with improved power and control.

- Durable construction withstands the toughest loading conditions and multiple life cycles.

PERFORMANCE AND PRODUCTIVITY

- Two engine emission options are available that meet U.S. EPA Tier 4 Final and EU Stage V emission standards or U.S. EPA Tier 2 and EU Stage II equivalent.

- More payload per pass on truck-loading applications with Performance Series Buckets.

- Payload increase to optimize pass on 775 trucks.

- Positive Flow Control (PFC) hydraulic system helps increase efficiency, bucket feel, and responsiveness with consistent performance.

- Excellent visibility to the bucket edges and work area through a Z-bar linkage.

- Planetary power shift transmission for maximum uptime.

- Convenient, responsive, electro-hydraulic controls increase operator productivity.

- Superior digging, high bucket fill factors, reduced dig times.

- Integrated steering and transmission controls.

- Operators can check tire pressure during operation with any change sending a fault code to VisionLink®, helping to prevent premature tire failure.

POWERFUL EFFICIENCY

- Increased efficiency material per gallon of fuel.

- Economy mode for reduced rated engine speed and reduced fuel consumption.

- Positive flow-control hydraulics for full flow on demand at low engine speeds.

- Engine Idle Shutdown for less fuel used while idling.

- Fully integrated electronic engine controls help make your fuel go farther.

PRODUCTIVITY WITH TECHNOLOGY

- Developed to monitor, manage, and enhance your jobsite operations.

- Payload provides accurate weighing* of the materials you are loading and hauling. Payload data is displayed in real-time to improve productivity and reduce overloading.

- Detect helps enhance awareness of the environment around working equipment and provides alerts to help keep people and assets safe on the jobsite.

- VisionLink wirelessly connects you to your equipment, giving you access to essential information you need to know to run your business.

- Gain valuable insight into how your machine or fleet is performing.

- Optional Advanced Productivity subscription helps provide comprehensive actionable information to help you manage and improve the productivity and profitability of your operations.

SAVE ON SERVICE AND MAINTENANCE

- 10% lower maintenance costs.

- Grouped service points.

- Electro-hydraulic controls.

- Swing-out engine compartment service doors.

- Ecology drains to prevent spills.

- Ground level access to transmission control valves.

- Vehicle Information Management System (VIMS™) notifications to resolve problems before failure.

- Long life, rebuildability, and high resale value.

SAFETY FIRST

- Standard stairway lighting.

- Left- and right-hand stairs with 45-degree angle.

- Standard Cat Vision, rear vision camera system.

- Pressurized cabin with filtered and reduced sound levels.

OPERATOR COMFORT AND CONTROL

- World-class operator comfort and ergonomics.

- Premium seat with heated and actively cooled leather, adjustable lumbar support, air adjustable bolsters on the seat and backrest, seat cushion tilt adjustment, and adjustable-length seat cushion.

- Easy-to-reach levers and controls with seat-mounted implement pod to reduce fatigue.

- Ergonomic switch placement and displays with large backlit switches, LED indicators, and ISO symbols.

- Optional heated mirrors.

- Two-position rocker switch activates the electro-hydraulic parking brake.

- Reduced vibrations from isolated cab mounts and seat air suspension.

- Automatic cab temperature controls.

- Achieve precise positioning for easy loading in tight areas with 35 degrees of steering articulation.

- Precise machine control by load-sensing hydraulic steering system.

PURPOSE BUILT SPECIALTY MODELS - MILLYARD

- Designed to meet the demands of millyard applications.

- Designed for durability, ensuring availability in multiple life cycles.

- Equipped with Economy Mode to save on fuel consumption by the use of On Demand Throttle.

- Equipped with Impleller Clutch Torque Convereter (ICTC) and Rimpull Control System (RCS) to reduce tire slippage and fuel efficiency.

- Full hydraulic flow down to 1,400 engine rpm by using hydraulic flow sharing technology.

- Equipped with 45 degree angle access ladders and standard Cat Vision for enhanced safety.

- Cat forks are designed for maximum productivity and durability.

- Integrates front camera mounting location for maximum visibility to the entire fork tips during truck unloading.

PURPOSE BUILT SPECIALTY MODELS - STEEL MILL

- World-class safety, operator comfort and efficiency in pit digging and skull handling applications.

- Efficiency of manual throttle and ergonomics of throttle lock.

- Excellent visibility to the bucket edges and work area through a Z-bar design.

- Equipped with extra heat protection to key hoses and harnesses for improved reliability.

LONG TERM VALUE AND DURABILITY

- World-class transmission for long life and consistent, smooth shifting; specifically designed for mining applications.

- Advanced filtration system for extended performance and reliability of the hydraulic system.

- Advanced Impeller Clutch Torque Converter (ICTC) and Rimpull Control System (RCS) reduce tire slippage and wear, improve fuel efficiency, and reduce cost-per-ton.

- Linkage pin joints have optional auto-lube system to ensure long life.

- Frame resists torsional shock and twisting forces.

- Heavy-duty steering cylinder mounts and axle mounting ensure increased structural integrity.

Standard Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

OPERATOR ENVIRONMENT

- Air conditioner and heater with automatic temperature control

- Cab, sound-suppressed and pressurized, rollover protective structure/falling objects protective structure (ROPS/FOPS)

- Cat Vision, rear vision camera system

- 12-volt power port

- Coat hook

- Cab precleaner, powered

- Electro-hydraulic tilt and lift controls (seat mounted)

- Flip-up armrest

- Heater and defroster

- CB radio ready

- Horn, electric

- Implement hydraulic lockout

-

Instrumentation, gauges:

– Engine coolant temperature

– Fuel level

– Ground speed

– Gear

– Hydraulic oil temperature

– Speedometer/tachometer

– Torque converter temperature

-

Instrumentation, warning indicators:

– Action alert system, three category

– Automatic transmission model enable status

– Brake malfunction

– Bucket float status

– Delayed engine shutdown status

– Engine idle shutdown status

– Engine malfunction

– Fuel economy mode enable status

– Hydraulic lockout

– Lockup clutch enable status

– Low fuel level

– Parking brake status

– Rimpull control enable status

– Seatbelt warning

– Secondary steering (if equipped)

– Throttle lock status

– Transmission gear

-

Keypad, control with indicator lights:

– Auto trans mode speed range

– Auto/manual transmission mode

– Fuel economy mode

– Implement kickout

– Lockup clutch

– Reduced rimpull

– Throttle lock

- Light, dome (cab)

- Lunchbox and beverage holders

- Mirrors, rearview (externally mounted)

- Premium seat with heated and actively cooled leather, adjustable lumbar support, air adjustable bolsters on the seat and backrest, seat cushion tilt adjustment, and adjustable-length seat cushion

- Seat belt, retractable, 76 mm (3 in) wide

- Steering and Transmission Integrated Control (STIC™) system with steering lock

- Tinted glass

- Trainer seat with lap belt

-

Vital Information Management System (VIMS™) with graphical information display: external data port, customizable operator profiles, cycle timer, and integral Cat Production Measurement

– Wet-arm wipers/washers (front, rear and corner) intermittent front wiper

-

POWERTRAIN

- Brakes, full hydraulic, enclosed, oil-disc

- Axle-shaft oil-disc service brake

- Electro hydraulic parking brake

- Case drain screens

- Cat clean emission module (CEM) - (Tier 4 only)

- Demand fan

- Engine Cat C27

- Fuel priming pump (electric)

- Ground level shutdown switch

- Mufflers (under hood) (Tier 2 equivalent only)

- Precleaner, engine air intake

- Radiator, Aluminum Modular (AMR)

- Separated cooling system

- Starting aid, (ether) manual override

- Throttle Lock

- Torque Converter, Impeller Clutch (ICTC) with lock-up clutch (LUC), and rimpull control system

- Transmission, 534 mm (21 in) planetary power shift (electronic) (3F/3R)

-

ELECTRICAL

- Alarm, back-up

- Alternator, 150 amp

- Batteries, maintenance free (2 – 1,400 CCA)

- Converter, 10/15 amp, 24V to 12V

- Deutsch component connectors

- Electrical system, 24V

- Electronic transmission control

- Lighting system, halogen (front and rear) lighting, access stairway, engine compartment

- Starter, electric

- Auxiliary start receptacle

-

OTHER

- Automatic bucket lift kickout/positioner

- Axle temperature sensor

- Battery disconnect and jump start receptacle, bumper

- Coupling, Caterpillar O-ring face seals

- Economy mode with on demand throttle

- Emergency platform exit

- Engine, crankcase, 500 hour interval with CH4

-

Engine idle management features:

– Auto idle kickdown

– Delayed engine shutdown

– Engine idle shutdown

- Fenders, steel (front)

- Guards, crankcase and powertrain

- Ground level lockable battery disconnect switch

- Grouped/labeled lube points

- Hitch, drawbar with pin

- Hoses, Cat XT™

- Oil sampling valves

- Positive flow control hydraulic system

- Product Link™

- Sight Gauges: hydraulic tanks, steering/fan and implement/brake, and transmission

- Stairway, left and right rear access

- Steering, load sensing

- Toe kicks

- Vandalism protection caplocks

- Venturi stack

- Premixed 50% concentration of extended life coolant with freeze protection to –34° C (–29° F)

Optional Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

POWERTRAIN

- –50° C (–58° F) antifreeze

- Engine oil change system, high speed, Wiggins

- Engine block heater 120V or 240V

- High ambient cooling – software

-

OPERATOR ENVIRONMENT

- Cat Detect, object detection system

- AM/FM/CD/MP3 radio

- Satellite Sirius radio with Bluetooth®

- LED warning strobe

- Mirrors heated

- Window pull-down visor

-

OTHER

- Front and rear roading fenders

- Fast fill fuel system (Shaw-Aero)

-

OTHER OPTIONAL CONFIGURATIONS

- Millyard

- Steel Mill